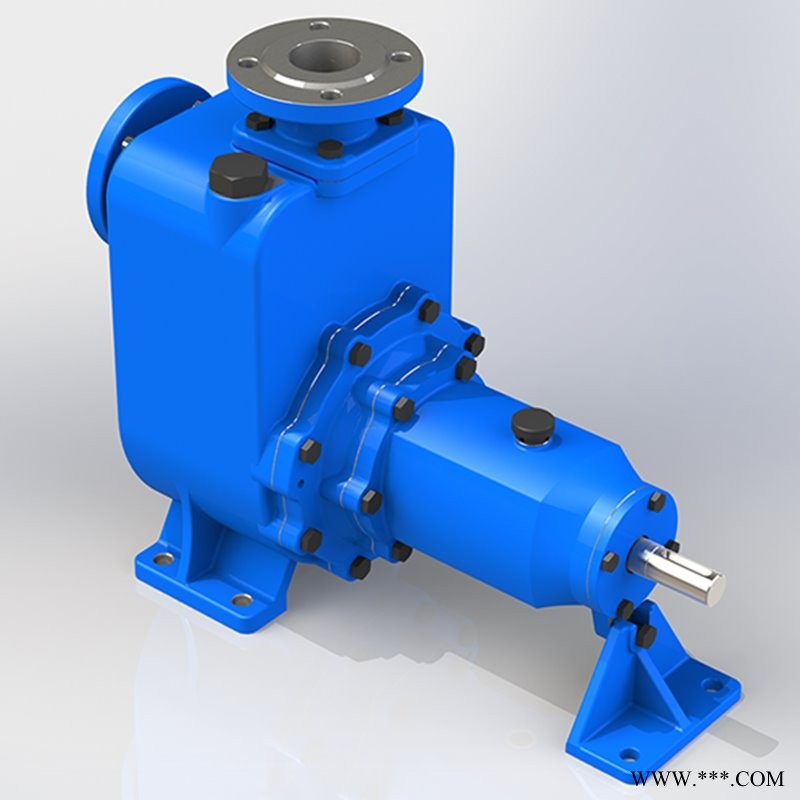

| 品牌 : | 帕姆泵科技 | 型号 : | 80CYZ-70 |

| 材质 : | 铸铁 | 性能 : | 自动 |

| 扬程 : | 70 | 驱动方式 : | 电动 |

| 输送介质 : | 油泵 | 泵轴位置 : | 卧式 |

| 叶轮结构 : | 半开式叶轮 | 叶轮吸入方式 : | 单吸式 |

| 流量 : | 60 | 叶轮数目 : | 1 |

| 汽蚀余量 : | 5 | 吸入口径 : | 80 |

| 排出口径 : | 80 | 结构原理 : | 中开泵 |

| 级数 : | 单级 | 重量 : | 150 |

| 电压 : | 380 | 功率 : | 22 |

| 轴功率 : | 0.88 |

自吸式离心泵80CYZ-70柴油输送泵 流量60立方扬程70米

自吸式离心泵80CYZ-70柴油输送泵 流量60立方扬程70米

●特点:

CYZ自吸泵属自吸式离心泵系列。具有结构简单、操作维护方便、运行平稳、排量大、效率高、便于调节,有较强的自吸能力,适用范围广等特点。

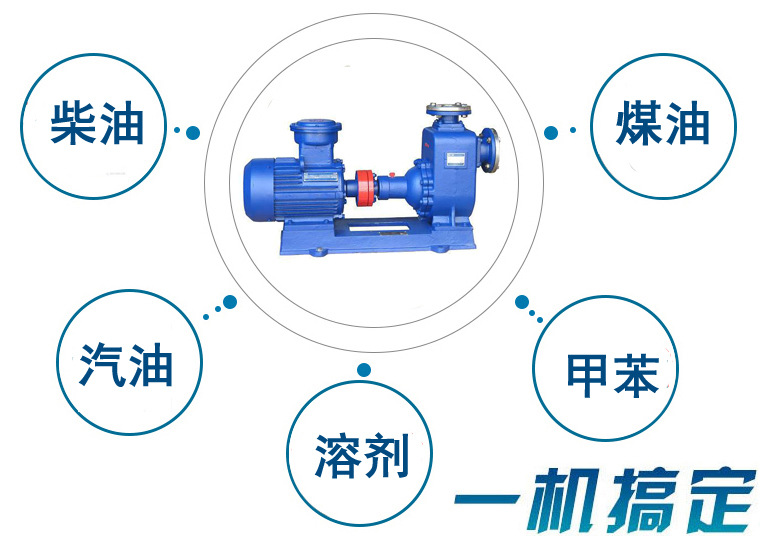

●用途:

CYZ自吸泵用来输送汽油、柴油、等石油产品。介质温度在-20℃~+80℃,是一种优良的船用装卸油泵,可兼作扫舱水泵。并适用于陆地油库、油罐车等储油装置的油料输送。也可以用来输送海水、淡水等。

●结构型式:

CYZ自吸泵采用轴同回液的泵体结构,泵体由吸入室、储液室、涡旋室、回液孔、气液分离室等组成。泵的轴承采用单列向心球轴承。在一些泵的轴承体底部设有冷却室。泵内部高、低压区间有密封环。轴端采用机械密封。

自吸油泵的基本构造是由六部分组成的分别是叶轮,泵体,泵轴,轴承,密封环,填料函。The basic construction of self-priming pump is composed of six parts, respectively, impeller, pump body, pump

shaft, bearing, seal ring, stuffing box.

1、叶轮是自吸离心泵的核心部分,它转速高出力大,叶轮上的叶 片又起到主要作用,叶轮在装配前要通过静平衡实验。叶轮上的内外表面要求光滑,以减少水流的摩擦损失。 1, is the core part of self-priming

centrifugal pump impeller, strength higher than that of its speed, leaf patches on the impeller and play a major role, the impeller through static balancing experiments before assembly.Impeller on

the inside and outside for smooth surface to reduce friction loss of water.

2、泵体也称泵壳,它是水泵的主体。起到支撑固定 作用,并与安装轴承的托架相连接。2, the pump body also calls the pump shell, it is the body of the pump.Support fixed effect, and connected to

install bearing bracket.

3、泵轴的作用是借联轴器和电动机相连接,将电动机的转距传给叶轮,所以它是传递机械能的主要部件。3, the role of pump shaft is connected by coupling and motor, the torque of the motor to the

impeller, so it is a major part of the mechanical energy transfer.

4、轴承是套在 泵轴上支撑泵轴的构件,有滚动轴承和滑动轴承两种。滚动轴承使用牛油作为润滑剂加油要适当一般为2/3~3/4的体积太多会发热,太少又有响声并发热!滑 动轴承使用的是透明油作润滑剂的,加油到油

位线。太多油要沿泵轴渗出并且漂贱,太少轴承又要过热烧坏造成事故!在水泵运行过程中轴承的温度 高在85度一 般运行在60度左右,如果高了就要查找原因(是否有杂质,油质是否发黑,是否进水)并及时处理!4,

bearing is set on the pump shaft support components of pump shaft, which has two kinds of rolling bearing and sliding bearing.Rolling bearing use butter as a lubricant oil is generally appropriate

for two-thirds to three-quarters of the volume too much will be fever, too little and there was a noise and fever!Sliding dynamic bearing is using a transparent oil as lubricant, go to the oil

level line.Too much oil leak to the pump shaft and floating base, too little bearing overheating and burn out cause an accident!In water pump bearing has the highest temperature during the

operation of 85 degrees in a running around 60 degrees, if the high will find reason (if there are impurities, oil is black, whether water) and processed in a timely manner!

5、密封环又称减漏环。叶轮进口与泵壳间的间隙过大会造 成泵内高压区的水经此间隙流向低压区,影响泵的出水量,效率降低!间隙过小会造成叶轮与泵壳摩擦产生磨损。为了增加回流阻力减少内漏,延缓叶轮和泵壳

的所 使用寿命,在泵壳内缘和叶轮外援结合处装有密封环,密封的间隙保持在0.25~1.10mm之间为宜。 6、填料函主要由填料,水封环,填料筒,填料压 盖,水封管组成。填料函的作用主要是为了封闭泵壳与泵轴之间的空

隙,不让泵内的水流不流到外面来也不让外面的空气进入到泵内。始终保持水泵内的真空!当泵 轴与填料摩擦产生热量就要靠水封管住水到水封圈内使填料冷却!保持水泵的正常运行。所以在水泵的运行巡回检查过程中对填

料函的检查是特别要注意!在运行 600个小时左右就要对填料进行更换。5, sealing ring, also known as minus leakage ring.import and pump impeller shell gap between the will build into water by means of

this clearance flow inside the pump high to a low pressure area, affect the water yield of pump, efficiency!Clearance starts to cause the impeller and pump casing friction wear.In order to increasethe flow resistance reducing internal leakage and delay the service life of the impeller and the pump shell, the pump casing and impeller around the foreign aid junction with sealing ring, sealinggap in between 0.25 ~ 1.10 mm is advisable.6, stuffing box is mainly composed of filler, seal ring, packing, packing gland, water tubes.The role of the stuffing box is mainly in order to close thegap between pump casing and pump shaft, don't let the flow within the pump does not flow outside to not let outside air into the pump.Always keeping the vacuum inside the pump!When the pump shaftand be about to rely on water seal packing friction heat to hold water to the water seal circle packing cooling!Keep the pump running.So in the process of pump run Tours of inspection to check thestuffing box is paying special attention to!Running about 600 hours will be carried out on the packing replacement.

自吸离心泵的过流部件 Self-priming centrifugal pump flow components

自吸离心泵的过流部件有:吸入室,叶轮,压出室三个部分。叶轮室是泵的核心,也是流部件的核心。泵通过叶轮对液体的作功,使其能量增加。叶轮按液体流出的方向分为三类: Self-priming centrifugal pumpflow components are: suction chamber, impeller, the pressure out of the room three parts.Room is the core of the pump impeller, and also the core of the flow components.Of liquid through theimpeller pump work, allow it to increase energy.According to the direction of liquid flow impeller is divided into three categories:

(1)径流式叶轮(离心式叶轮)液体是沿着与轴线垂直的方向流出叶轮。 (2)斜流式叶轮(混流式叶轮)液体是沿着轴线倾斜的方向流出叶轮。 (3)轴流式叶轮液体流动的方向与轴线平行的。

叶轮的分类

叶轮按吸入的方式分为二类:

(1) 单吸叶轮(即叶轮从一侧吸入液体)。 (2) 双吸叶轮(即叶轮从两侧吸入液体)。

叶轮按盖板形式分为三类: (1) 封闭式叶轮。 (2) 敞开式叶轮。 (3) 半开式叶轮

According to the classification of the impeller impeller suction way is divided into two categories:

(1) single suction impeller (i.e., from one side suction impeller liquid).(i.e., (2) double suction impeller impeller from either side suction liquid).

Impeller press flat form is divided into three categories: (1) closed impeller.(2) open type impeller.(3) half open impeller